SUPERGEN

SuperGen is a combination of variable speed generator and ultracapacitor, which has been specially designed for super diesel fuel efficiency and high level of variable loads.

OUR SUPERGEN SYSTEM

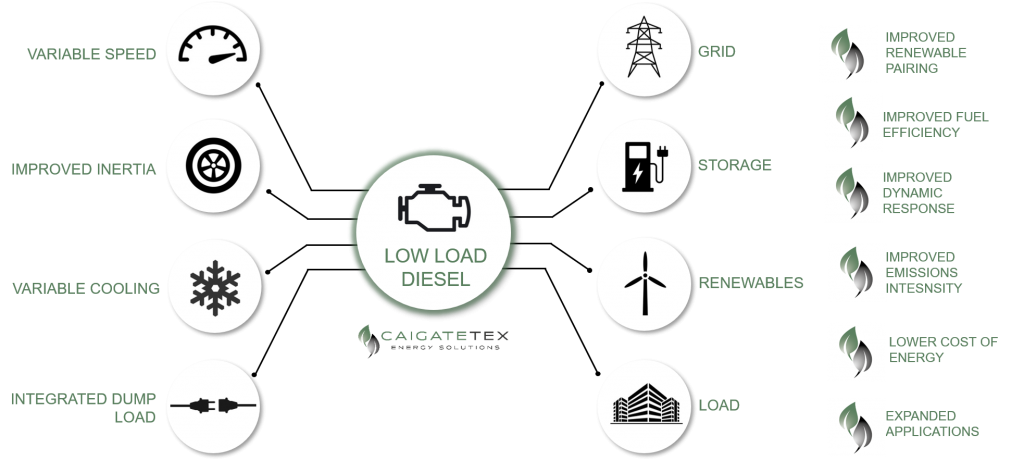

Conventional diesel generators run at a fixed speed at 1500 or 1800 rpm for 50Hz or 60Hz systems respectively, while variable speed diesel generators can run at preferred speed according to the best fuel efficiency, the engine speed will be varied and be determined by the output power. The generator is still able to meet the 50Hz or 60Hz system frequency, as a power converter is placed between the generator and the load.

The role of the power converter is to ensure the variable frequency output of the generator is conditioned to meet the network frequency. This approach is common across wind, solar PV and battery technologies, which generate at either variable speed or are direct current technologies.

Reliance on a power converter does not reduce the reliability of the approach, however it does improve the power quality and security which can be offered to support the network, especially applied with the ultra-capacitor, it can stabilise the power supply by buffering the varied loads and reducing the impact to the engine.

WHAT IS IT?

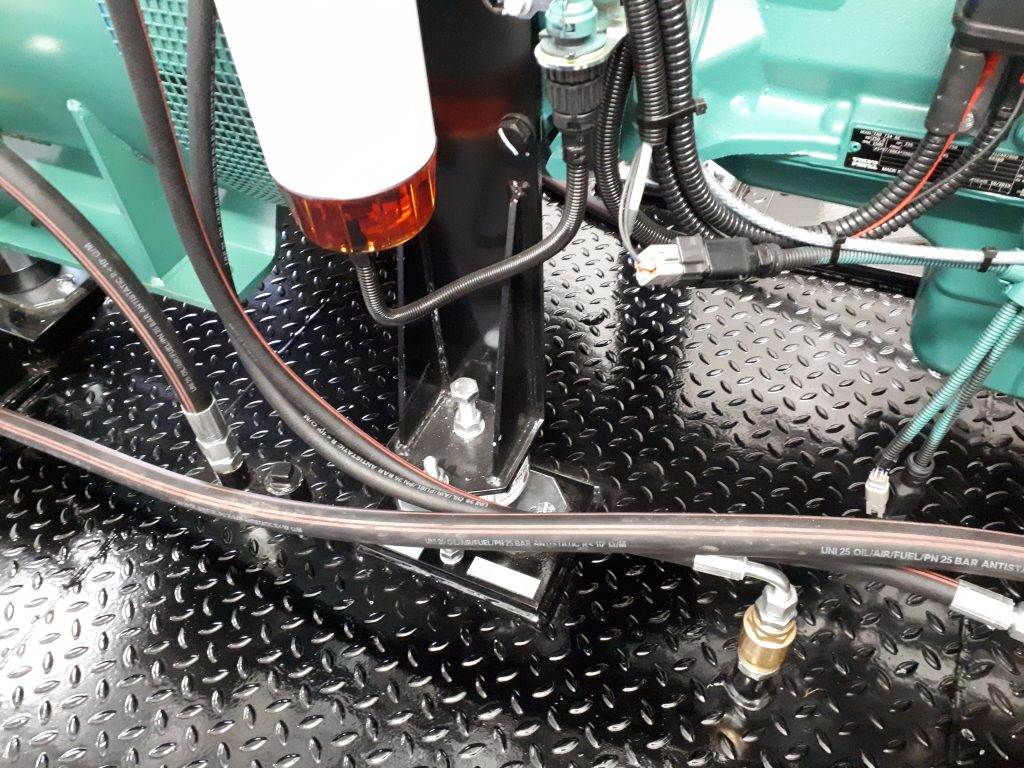

SuperGen: variable speed generator with separately enclosed ultracapacitor

SPECIALITY:

Coping with high impact load profile

FUEL

Excellent fuel efficiency, ROI 2-3 years

OUTPUT

DC output for RGT, drill rig, marine, mining machine, and other DC consumers

The ability of the variable speed generator to select its preferred speed setting is responsible for the dramatic performance improvements. The generator is no longer constrained to a fixed speed which enable the generator significantly reduced the fuel consumption particularly at lower level of load. Meanwhile, the engine reliability and lifetime can be significantly improved.

On the other hand, SuperGen has the capability to maximise the potential of the generator by running the engine at higher speed to supply extra power at demand. The optimum efficiency for higher load being at higher speed. Off-grid system operators are increasingly turning to wind and solar generation to lower their diesel fuel consumption. Unfortunately, they quickly hit a technical barrier, with the operability of conventional diesel generation constraining the possible renewable energy penetration.

One solution has been developed in variable speed diesel technology.

SuperGen application allows a diesel engine to operate at its most efficient speed reference, providing for improved engine flexibility and response. SuperGen can significantly reduce the cost of high penetrations of renewable energy into remote and off-grid power systems, without substantially changing the technology footprint. SuperGen utilises Caigatetex Power Hub converters with additional load monitoring and speed control feedback. Accordingly SuperGen has a pivotal role in transitioning off-grid power systems to a reduced reliance on diesel fuel with the associated longer term commercial benefits.

Applications:

Based on the advanced key features (fuel saving, reduced carbon emission, enhanced and stabilised power, improved reliability and extended lifetime) of SuperGen, it will expand the application into wide industries, where the load variations are very high, and the average load used to be very low, not only the best partner of renewable energy like wind, solar power, but also the engineering machines, such as the harbour RTG, mining drillers, gas and oil machines, marine, etc. SuperGen is one of the key elements for off grid or microgrid systems.

Fuel:

With fixed speed generators the fuel usage drops with load demand fall off but as the nominal speed for all loads is fixed, the engine is not working at its optimum fuel efficiency. With the ability to monitor exact electrical load, converted to an engine mechanical load requirement, the variable speed engine can be signalled to run at a lower speed to achieve the required load, resulting in an improved fuel efficiency. Fuel consumption savings depend on load and speeds but savings of between 10% and 20% can be made in Litres/hour consumption, which for lower average load demands and specific running cycles will result in excellent fuel efficiency, with Recovery Of Investment in the increased alternator and converter costs, typically within 3 years.